Our

Company

KAN Engineering is a UK-based fast-growing high-tech start-up founded in 2018 by Dr. Amir Soltani (former lecturer at Cranfield University). KAN Engineering is driven with a team of world class engineers and experts with a successful track record working on numerous leading-edge projects within the automotive sector.

We provide advanced simulations products and services for the development, testing and validation of automotive applications. These include Electric, Connected and Autonomous Vehicles (ECAV) and their associated products and systems. We use the latest technologies, tools, and techniques to study, develop and implement the best solution for our customer's needs.

We have developed and delivered innovative distributed simulation environments, simulators and HiL rigs for several industrial and academic organisations, including UTAC (Millbrook) Proving Ground, Zenzic, Imperuim Drive, Cranfield University and City University of London.

We also have successfully collaborated with several global Testbeds, OEMs, R&D Centers, including Ford UK, UTAC (Millbrook), HORIBA MIRA, IDIADA, WMG, SMLL (TRL), University of Leeds and SteertDrone amongst many more, to develop numerous award-winning projects and world leading solutions on advanced simulation.

KAN Engineering is an active member of ASAM, where we are directly involved in the development and implementation of new OpenX standards. KAN Engineering is officially recognised on the Zenzic CAM CREATOR Map: contributor to UK Connected and Automated Mobility Roadmap to 2030! We are also a member of Cranfield Barclays Eagle Lab, the innovation centre jointly supported by Barclays Bank and Cranfield University.

Our team is committed to continuous innovation and excellence to become global pioneers in advanced simulation technology for future mobility. We will achieve this by offering world-class solutions and cutting-edge products, tailored to every individual customer's need.

Our team is committed to continuous innovation and excellence to become global pioneers in advanced simulation technology for future mobility. We will achieve this by offering world-class solutions and cutting-edge products, tailored to every individual customer's need.

Featured

Projects

We have substantial knowledge and experience gained from long term contributions in many multi-disciplinary technology development projects.

Featured

Projects

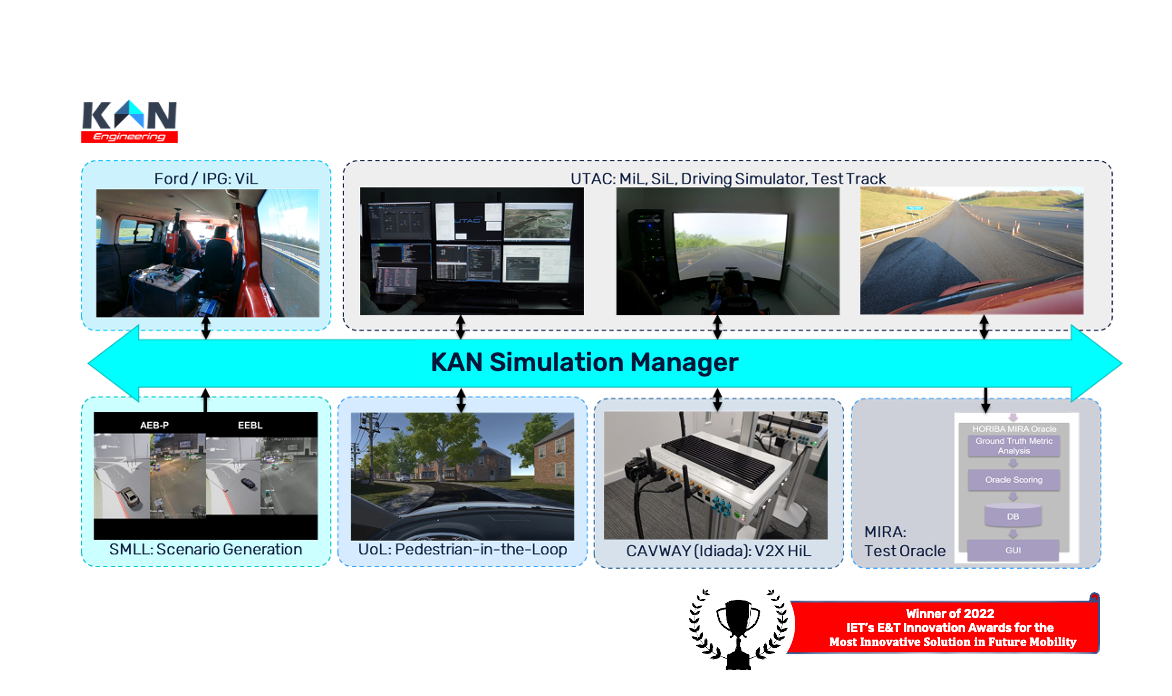

Zenzic Interoperable Simulation Across CAM Testbed UK Phase 3

In continuation to Zenzic phase 2, phase 3 exhibited collaborative efforts with Ford Motor Company, UTAC, SMLL, Applus IDIADA, HORIBA MIRA, WMG and University of Leeds towards a common goal to build a technically robust and financially cost-effective solution for distributed real-time co-simulation capabilities across CAM Testbed UK and beyond. KAN Engineering contributed to this novel project as the technical lead and system integrator. This project has won the IET Awards 2022 for the "Most Innovative Solution for Future Mobility".

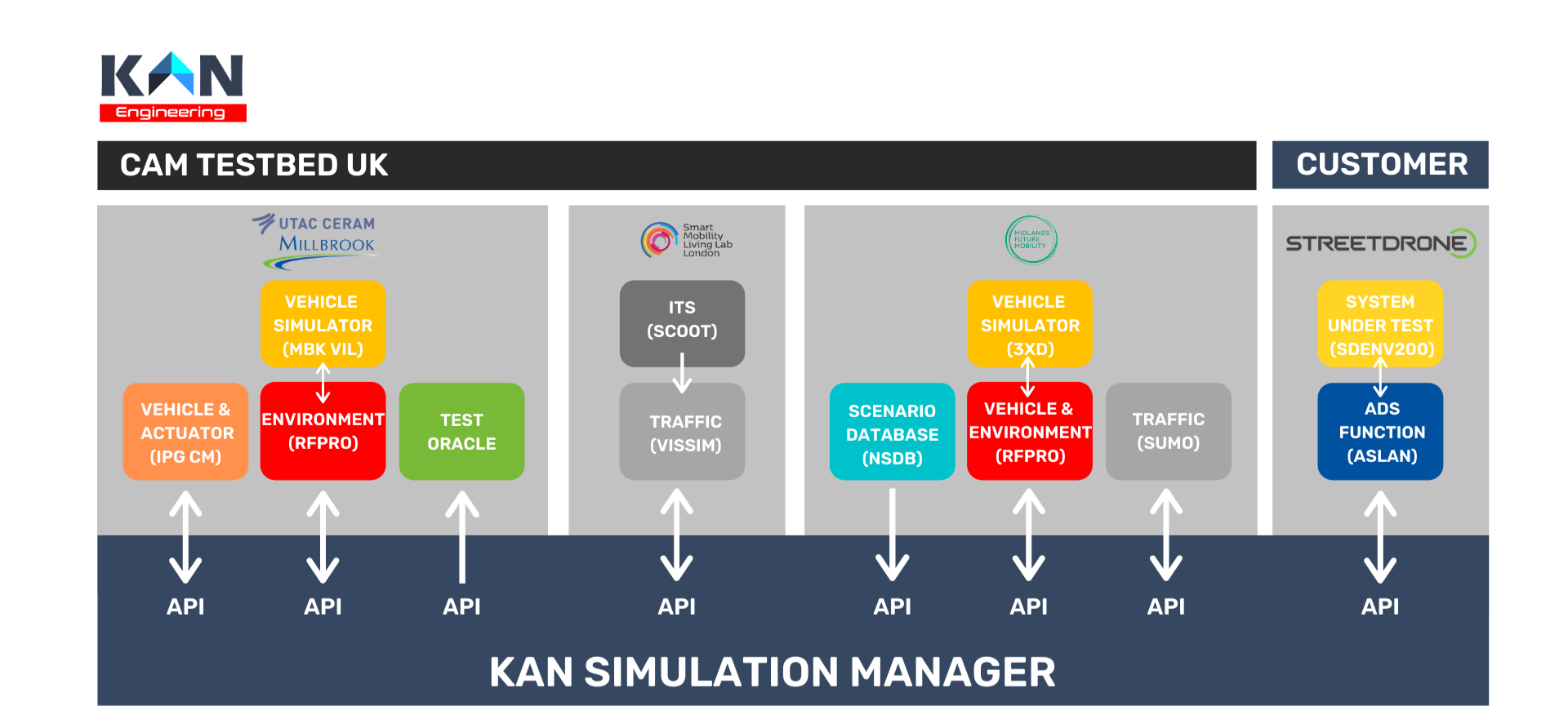

Zenzic Interoperable Simulation Across CAM Testbed UK Phase 2

A collaboration with Millbrook, Midlands Future Mobility, WMG and Smart Mobility Living Lab: London as the selected testbeds to provide StreetDrone as the end-user customer with a seamless testing experience across their interoperable simulation testing capabilities. This proof-of-concept was demonstrated as a word-class solution to the challenge of providing a comprehensive virtual testing environment and foundation for the future of interoperable simulation. Read the Full Report Here

Full Vehicle Simulator HiL Rig for ADAS Applications

Full Vehicle Simulator HiL Rig for ADAS Applications

Designed to integrate both the human driver and the control software stack with real sensors and actuators in the vehicle with a wide range of simulation software and hardware, complete with real-time capable wheel steer actuation and a 210 degree curved projection screen for a more realistic simulation experience. Connects SiL, HiL and ViL testing levels in the development process to enable repeatable testing of multiple scenarios using a flexible combination of real-world components and simulated systems.

Integrated with a Wide Range of Software including IPG CarMaker, VI-Grade, rFpro, SCANeR, Aimsun, SUMO, Claytex, Concurrent HW (iHAWK) and SW (SimWB), ...

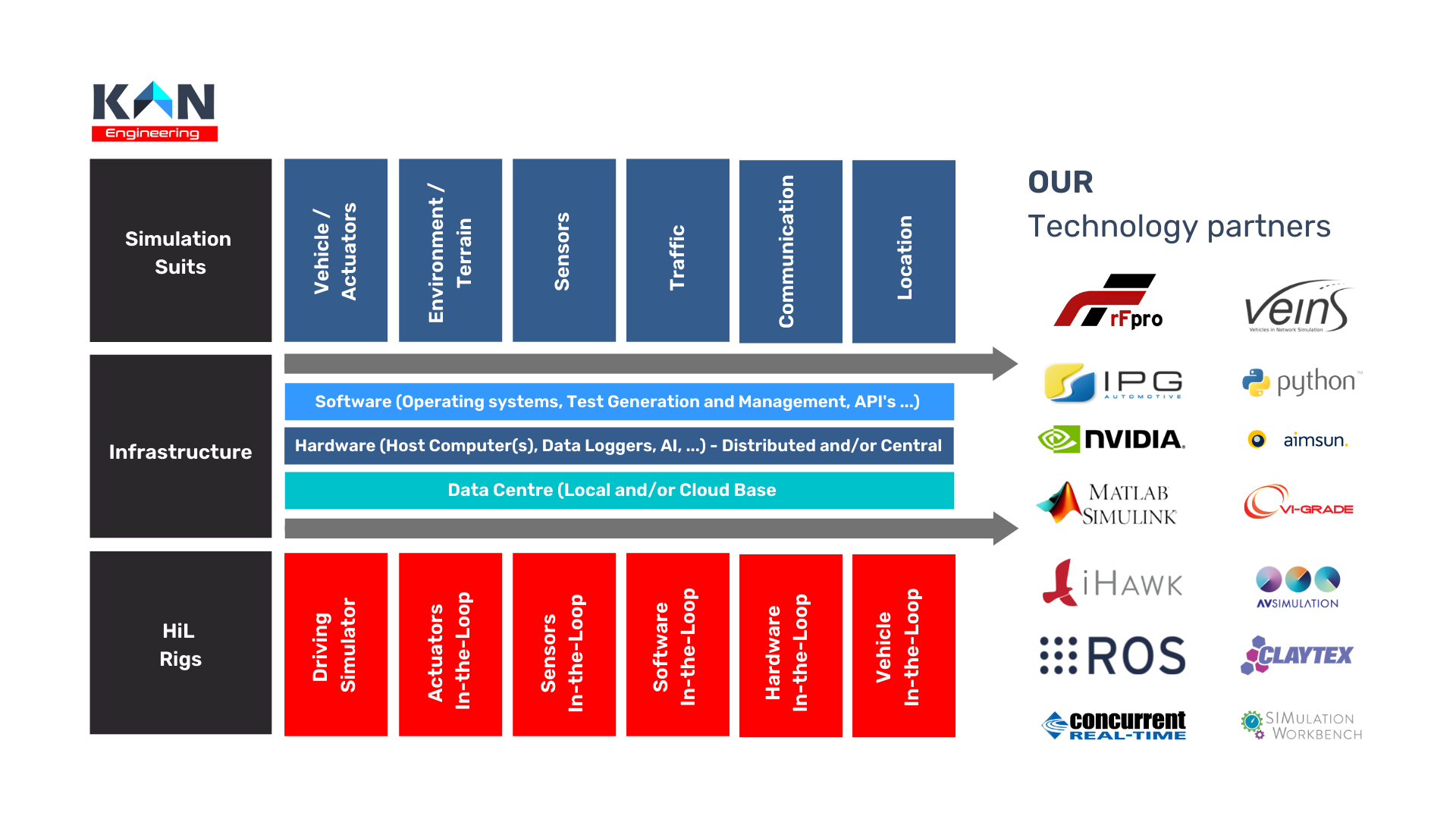

Integrated Simulation Environment for Autonomous Vehicle Applications

Integrated Simulation Environment for Autonomous Vehicle Applications

Real-time capable, distributed simulation enabled, data-centric, tool-agnostic platform to seamlessly work with any number of software and hardware for development, testing and validation of a wide range of ADAS & CAV systems. Currently supports and integrates seamlessly with a wide variety of software, including but not limited to: rFpro, SCANeR, IPG Carmaker, VI-CarRealTime, SimWB, Aimsun, SUMO, and PTV Vissim. The flexible API and data architecture provides easy access to manage both the simulation orchestration and data based on ASAM-OSI standard.

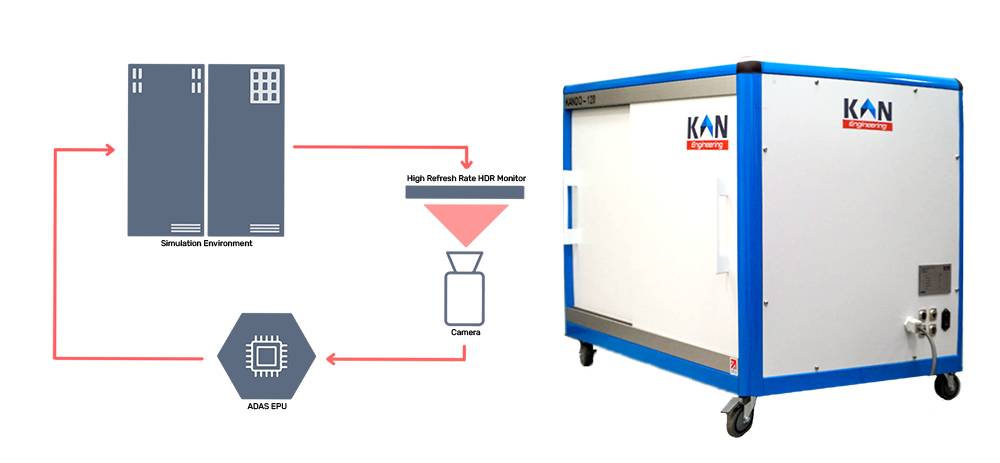

ADAS Camera HiL

ADAS Camera HiL

Customisable platform to integrate automotive grade camera with the simulation image generators to enable realistic testing of algorithms such as localisation and perception of the control software stack. Customers can connect their camera-based hardware to our simulation platform the progress from MiL to HiL testing with minimal hassle.